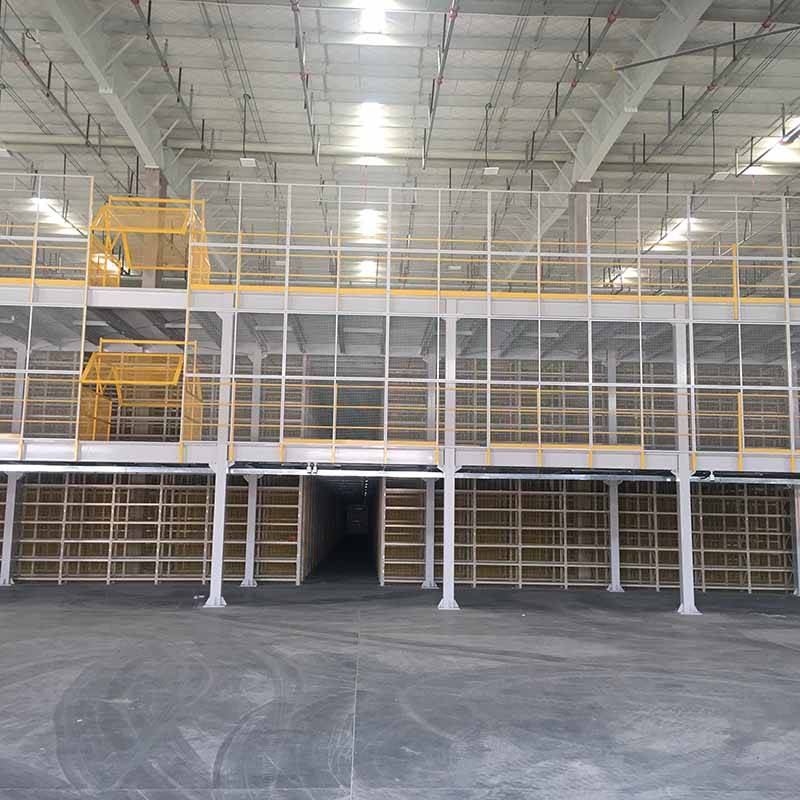

Mezzanine

Short Description:

Mezzanine rack takes advantage of vertical volumetric space in the warehouse, and uses medium-duty or heavy-duty rack as the main part, and solid steel checkered plate or perforated plate as the flooring.

Mezzanine rack takes advantage of vertical volumetric space in the warehouse, and uses medium-duty or heavy-duty rack as the main part, and solid steel checkered plate or perforated plate as the flooring. Racking supported mezzanine uses racking system's parts to add a second or third level inside your warehouse to create more usable space.

The typical load capacity of mezzanine is 300kg-1000kg/sqm. It is widely used for high warehouse for small goods with manual access making full use of the space in the warehouse. According to the actual field and specific requirements, it could be designed in single or multiple layers, usually 2-3 layers, it is specifically used for sorting storage of automotive fittings or electronic devices carrying less than 500kg per layer. The usual ways of transportation from 2nd floor to 3rd floor are manual, elevating table, hosting machine, conveyor and forklift truck.

Components: Steel Platform is made up of column, main beam, secondary-beam, steel flooring, staircase, handrail, horizontal bracing, back bracing, connecting plate and some accessories.

Mezzanine can make best use of the warehouse space. It is widely applied to auto parts, 4S stores, in order to adapt to the requirement of the market. Basing on the requirements of automotive fittings warehouse, HUADE has developed mezzanine rack for tires, vehicle body components, various plastic cartons and boxes storing small components.

Mezzanine racks are dismountable and re-usable, and the structure, dimensions and location of mezzanine could be easily modified. It can be equipped with lights, decking handrails, shelves, staircase and many other options.

Floor panel with small/large load capacity, low cost and quick construction

Can be designed into one layer or multiple layers according to requirement

Almost fullest space utilization

Direct access to all goods

Surface: Powder coated or galvanized

Transportation methods between layers:manual, elevating table, hoisting machine, conveyor, forklift truck.

Customizable according to clients' specific requirements.