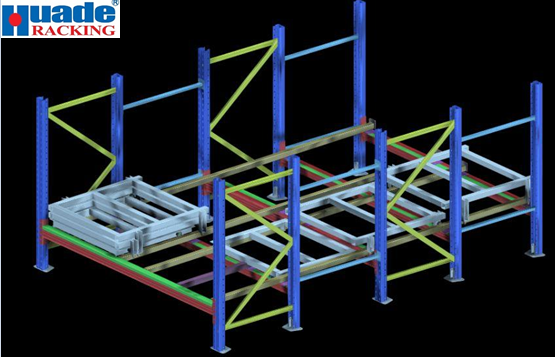

Huade Push Back Rack

Short Description:

The push back racking adopts the principle of combining rail and pallet cart to move pallets in the lane, the rail is at a certain slope. The gravity of the goods is used for retrieval of palletized goods. The palletized goods are regulated and stored at one end. The storage of large quantities and small varieties of goods has a high space utilization rate and it is more flexible and convenient to access. and ideally, the weight of each goods with pallet shall not be more than 1500 kg.

The push back racks are divided into single and double positions, Structural components of push back racks are: uprights, bracings, row spacers, beams, hang beams, pallet support bars, pallet carts, rails.

Based on different loading capacity of the pallet, there are many uprights, bracings, beams available with different profiles to be chosen.

The profile of upright can be 85/100/120mm for different loading capacities.

The fuction of the row spacer is to connect the upright frames. Double row spacer connects 2 nos of the upright frames while single row spacer connects the independent upright and the upright frame.

Each level of beams consists of 1 no of front and back beam, several middle beams.

Pallet cart is a wheeled frame, Composed of square tube, iron angle steel and single-shaft bracket, welded and formed, equipped with load-bearing shaft, guide shaft, special bearing and anti-collision rubber block.

Trolley is not required for the goods with pallet stored at the front.

Rails are made by hot-dip galvanized square or rectangular hollow section tubes.

All the parts are assembled like in the following picture:

The advantages of the push back rack:

1) It saves the number of aisles for forklift to work through.

2) It increases the space utilization rate, at the same time it doesn’t require high forklift.

3) It is mainly used in places where the warehouse space is insufficient

Written by Barry Zhang